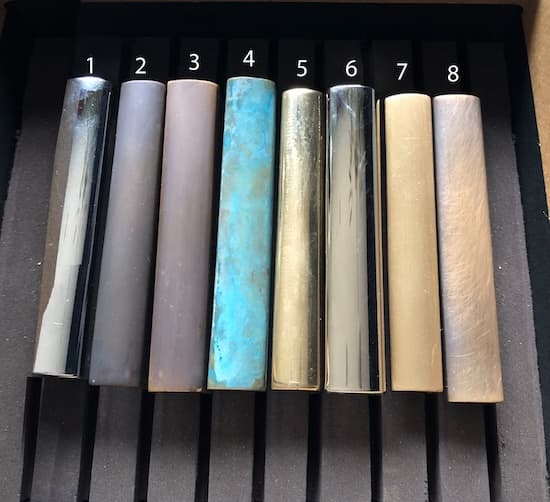

Materials

Every piece begins with carefully selected metals and finishes — chosen for beauty, durability, and precision.

A diverse material range is available for use with all Rowland commissions.

Brass

Warm, tactile, and timeless. Polished or aged, brass adds subtle richness to bespoke interiors.

Copper

A metal of depth and heritage. Perfect for sculptural details and patinated finishes. Develops a unique character over time.

Stainless Steel

A versatile alloy available in many grades, engineered for applications ranging from fine detailing to extreme industrial environments.

Aluminium

A lightweight, highly workable metal — around ten times lighter than platinum. Favoured for its strength-to-weight ratio and adaptability across precision manufacturing.

Platinum

The high priestess of precious metals. Heavier than lead and higher in value than gold. It takes 8 tons of mined ore to produce just 1 ounce of the pure metal. it is virtually impervious to oxide attack. not easily worked.

Silver 925

Pure silver and its compounds have many uses. it has been found to be a powerful antibiotic when ingested. It has a distinctive whiteness about it when polished, though this is short-lived as it tarnishes and dulls if left unmaintained.

18 ct White Gold

Often used to substitute platinum. this alloy of gold contains 75% gold with the remaining percentage shared with silver and palladium. easy to work but with a greyish colour a preference to see this metal rhodium plated is common.

9 ct White Gold

Contains over 60% silver giving it a whitish lustre. commonly used as a higher value alternative to silver. works with relative ease.

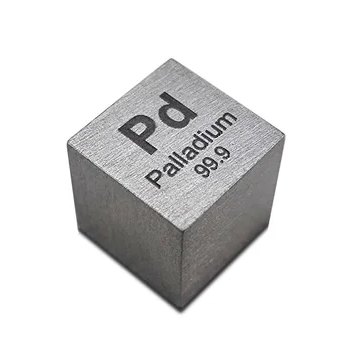

Palladium

Used widely in the medical electronic and jewellery industry. incredibly palladium left undisturbed at room temperature will absorb 900 times it's own volume of hydrogen.

High Carbon Steel

High-carbon steel contains a higher carbon content (typically 0.6–1.0%), giving it exceptional hardness, strength, and edge retention. It is ideal for cutting tools and precision components but is more brittle and requires protection against corrosion.

Mild Steel

The most common metal used in industry. Easily worked, though not excessively so, it will almost always require surface treating as it’s pure form readily oxidises within minutes. Electroplates very well.

Titanium

The most common metal used in industry. Easily worked, though not excessively so, it will almost always require surface treating as it’s pure form readily oxidises within minutes. Electroplates very well.

Chrome

Chromium is what gives ruby’s their red colour. Can be alloyed with mild steel to make stainless steel. It’s salts when dissolved in solution, can be used to chrome plate many different metals. one of the brightest most durable finishes.

Nickel

Used as a base for chrome in the chrome plating process and has been used to compound alloys in coins for centuries, in recent years it’s use with jewellery alloys has been restricted as it can cause skin reactions.

White Metal

An alloy of exceptionally low melting point. specific grades will melt in hot water ! Can be used to cast small intricate objects such as toy soldiers or door handles.

Zirconium

A metal of high corrosion resistance used in surgical instruments when alloyed with other metals. It is a common element found on the surface of the moon and other uses include artificial limb manufacture.

Tantalum

Used in the electronics industry for capacitor and resistor manufacture. its a compound element for alloy fortification and causes no immune response when inside the body. With this in mind it can be used for the production of dental alloys.

Niobium

A metal with exception al heat resistance it’s alloyed with other elements in stainless steels and also in alloys with a variety of nonferrous metals, such as zirconium. The metal is used in superalloys for jet engines and heat resistant equipment.

Tin

A soft silver metal with a yellowish hue. Alloyed with many metals notably lead to produce solder. When a bar of tin is bent, the so-called tin cry can be heard as a result of sliding tin crystals reforming.

Lead

A dense, soft, and highly malleable post-transition metal. Prized for its **corrosion resistance** and **high density**, it has been historically used in plumbing, pigments, and radiation shielding. Due to its toxicity, its use is now highly regulated, especially in consumer products.

Metal Finishes

- Chrome

- Dark bronze patination applied to brass

- Light bronze patination applied to brass

- Verdigris applied to brass and copper

- Gold plating applied to all metals

- Decorative nickel

- Brushed brass

- Brushed semi-patinated brass

Finishes shown are stable and durable. Verdigris, however, is more delicate and should be used in areas where it will remain largely untouched, as heavy handling can reduce the blue oxide surface. Lacquers may be applied to further protect patinated and oxide finishes.